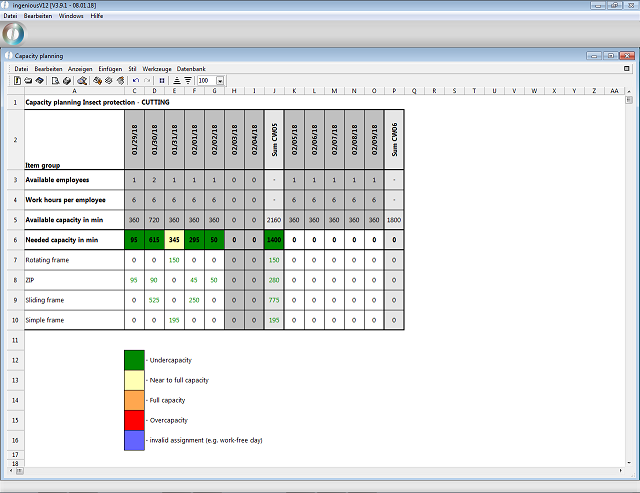

Capacity planning can calculate the actual available maximum capacity on a daily basis instead of using static values.

To determine these available times, the Resource planning was added.

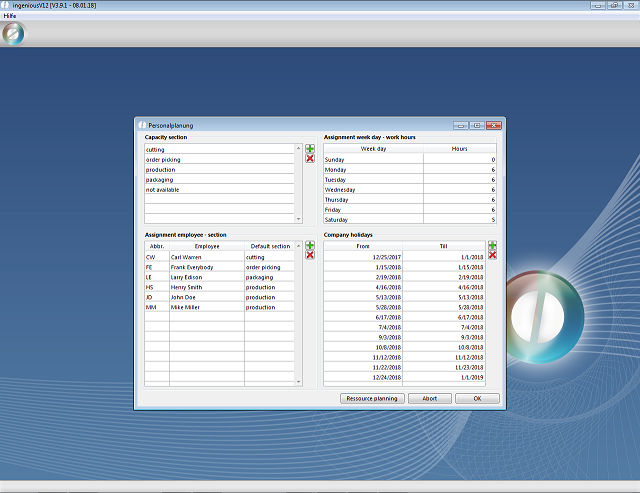

Here you can manage centrally the different production areas, which correspond to individual capacity planning, the production staff, available working hours per day of the week and the company holidays.

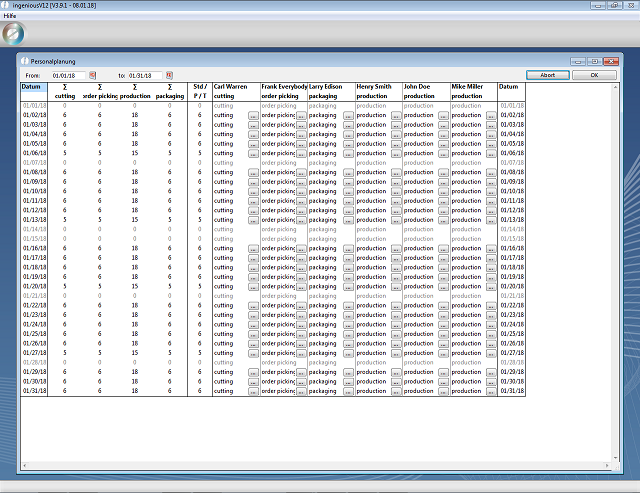

Based on this data, you can switch to the resource planning board, where detailed planning tales place.

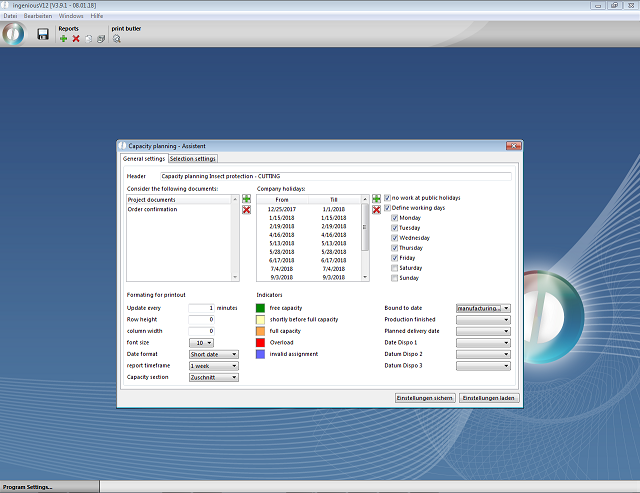

Hereafter, the part lists have to be extended by help articles to the single production areas.

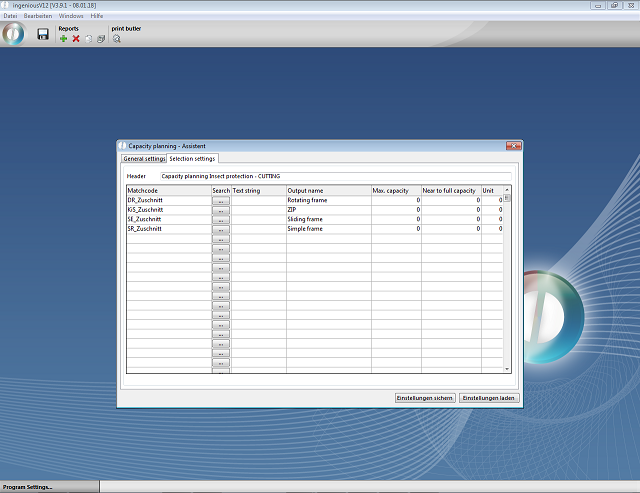

They have to be defined as time items. The capacity planning settings have to refer to these help articles. Additionally, the capacity section has to be selected.

The extended capacity planning then compares the available times to the required ones.